Pour Point Process Analyzer

Benefits

- ASTM compliant measurement based on tilting mechanism

- Low and high temperature applications

- Opacity independent measurement

- Network and fieldbus communication

Marking

ATEX: II 2G Ex h IIC T4 Gb X

IECEx: Ex IIC T4 Gb

NEC 500: Class I, Division 2, Group B,C and D

NEC 505: Class I, Zone 1, AEx d e ib px IIB

resp. IIB+H2 T3 resp. T4

CEC Sec. 18: Ex d e ib px IIC T3 resp. T4

TR CU: II Gb T4 X

Ambient Temperature

T4Description

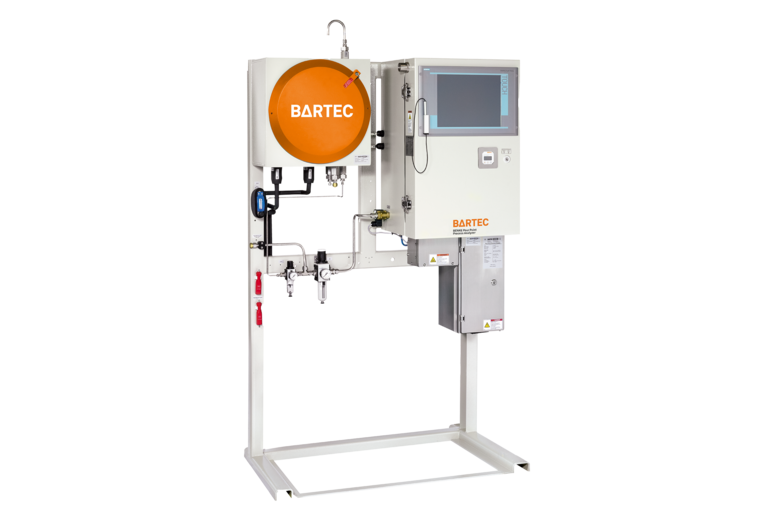

To remain competitive, today’s refiners must employ all optimization and product control techniques available. The use of online physical property analyzers is one of the key features to reach those objectives because they measure important quality properties in the process directly.

The pour point of a liquid is the temperature at which it still flows but starts losing its flow characteristics by becoming semi solid. For hydrocarbons the pour point temperature depends on the content of paraffin in the liquid but also on the viscosity that changes with temperature. The pour point temperature is an important quality parameter especially for lube oils but also for gas oils and fuel oils.

Technical Data

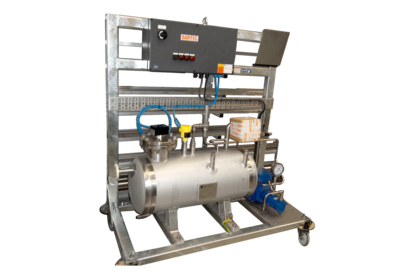

| Technology | automatic tilting measuring cell |

|---|---|

| Method | compliant with: ASTM D97, DIN EN ISO 3016, IP 15 correlates with: ASTM D5949 Automatic Tilt Method similar to ASTM D5950 |

| Sample at inlet | filtered 50 μm, free of suspended water (≤ 37 cSt at inlet temperature) approx. 20 to 40 l/h 1 to 3 bar (14.5 to 43.5 psi) normal: 30 to 50 °C (86 to 133 °F) min. 20 K above pour point temperature |

| Sample at outlet | atmospheric pressure |

| Electrical data | max. 8 (4 to 20 mA; 1000 Ω); active isolated on request 4 to 20 mA; 160 Ω 24 V DC; max. 0.5 A high: 15 to 28 V DC low: 0 to 4 V DC 24 V DC; max. 0.8 A |

| Communication | MODBUS/RTU via RS485 or RS422 or FOC is MODBUS/TCP via FOC is pour point temperature (others on request) Alarm, Ready/Valid Stream Selection, Validation Request, Reset via Ethernet (VDSL or FOC is) |

| Ambient conditions | operation 5 to 40 °C (41 to 104 °F) storage -20 to 60 °C (32 to 140 °F)+ operation 5 to 80 % relative humidity, non-corrosive; storage 5 to 80 % relative humidity, non-corrosive IP 54 (comparable with NEMA 13) |

| HMI | touch display 19" remote access on request cyber security operating system Windows10 enterprise LTSB Bartec Benke control software PACS |

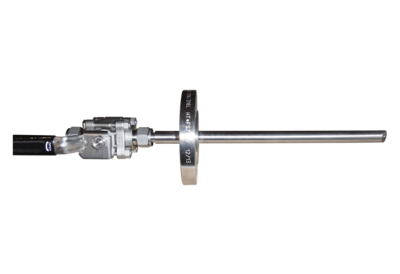

| Process connections | tube fittings: typically Swagelok 6mm/12mm/18mm; others on request sample inlet up to 2 sample streams and 1 validation stream sample outlet vent line (if required) coolant (if required) |

| Weight and dimensions | approx. 300 kg (without options) approx. 1140 x 1900 x 710 mm free space right: 150 mm/left: 100 mm |

Questionnaires/Requirement Sheets

-

Questionnaire_PL AMS_PAT

Data Sheets

-

BENKE Pour Point Process Analyzer PPA-4