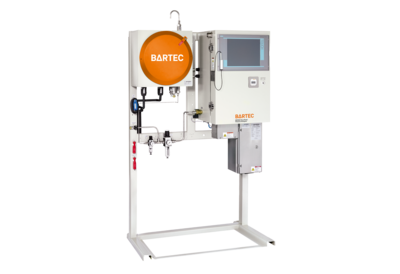

Vapor Pressure Process Analyzer

Benefits

- ASTM compliant cylinder piston design with 4:1 expansion

- Suitable for high pressure applications (LPG)

- Suitable for high viscous samples (Crude Oil) without flushing cycles

- No maintenance approach

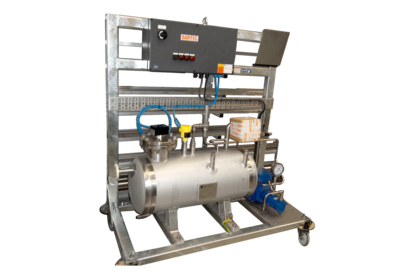

- Integral temperature control unit

- Network and Modbus communication

Marking

ATEX: II 2G Ex h IIC T4 Gb X

IECEx: Ex IIC T4 Gb

NEC 500: Class I, Division 2, Group B,C and D

NEC 505: Class I, Zone 1, AEx db eb ib pxb IIC T3

resp.T4

CEC Sec. 18: Ex db eb ib pxb IIC T3 resp.T4

TR CU: II Gb T4 X

Ambient Temperature

T4Description

To remain competitive, today’s refiners must employ all optimization and product control techniques available. The use of online physical property analyzers is one of the key features to reach those objectives because they measure important quality properties in the process directly. The vapor pressure is an indication of a liquid evaporation rate and relates to the tendency of volatile components to escape from the liquid. To assure safe storage and transportation of petroleum products, minimize environmental pollution and assure proper functioning of combustion engines it is important to measure the vapor pressure.

Technical Data

| Technology | expansion with piston 4:1 expansion |

|---|---|

| Method | compliant: ASTM D5191, DIN EN 13016-1, ASTM D6377 (VPCR4) fuel up to 1.6 bar (23 psi), LPG up to 16 bar (232 psi) ≤ DIN EN/ASTM, fuel typ. 1.5 mbar (0.02 psi), LPG typ. 50 mbar (0.73 psi) ≤ DIN EN/ASTM discontinuous, cycle time 7 min typically, depends on sample composition |

| Sample at inlet | filtered 10 μm, moisture content max. 500 ppm, ≤ 200 cSt at inlet temperature pour point 15 K below measuring temperature or cloud point temperature; for crude oil applications WAT needed approx. 2 to 10 l/h (depends on product); approx. 30 l/h for re-cooling of peltier device; (not required if suitable coolant is available) min. 2 bar (29 psi) above measuring range; standard: up to 8 bar (116 psi); optional: up to 18 bar (261 psi) Standard: TM** 45 °C: TM**-40 K TINLET *** max. 45 °C(113 °F) Optional: TM**> 45 °C: TM**-30 K TINLET *** TM**+5K variation of temperature should not exceed 0.2 K/min |

| Sample at outlet | can handle back pressure (on request) |

| Electrical data | max. 8 (4 to 20 mA; 1000 Ω); active isolated on request 4 to 20 mA; 160 Ω 24 V DC; max. 0.5 A high: 15 to 28 V DC/low: 0 to 4 V DC 24 V DC; max. 0.8 A |

| Communication | MODBUS/RTU via RS485 or RS422 or FOC is MODBUS/TCP via FOC is ethernet available vapor pressure (others on request) Alarm, Ready/Valid; Stream Selection, Validation Request, Reset |

| Ambient conditions | operation 5 to 40 °C (41 to 104 °F); storage -20 to 60 °C (-4 to 140 °F) operation 5 to 80 % relative humidity,storage 5 to 80 % relative humidity, – both are non-corrosive IP 54 (comparable with NEMA 13) |

| HMI | touch display 19" remote access on request cyber security operating system Windows10 enterprise LTSB Bartec Benke control software PACS |

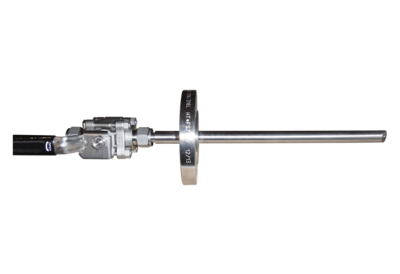

| Process connections | tube fittings: typically Swagelok 6mm/12mm/18mm; others on request sample inlet up to 2 sample streams and 1 validation stream sample outlet vent line (if required) coolant (if required) |

| Weight and dimensions | approx. 250 kg (W x H x D) approx. 1190 x 1930 x 710 mm free space right: 150 mm/left: 100 mm |

Application Notes

-

HYGROPHIL F 5673 & RVP-4 Process Trace Moisture Analyzer and Reid Vapour Pressure Analyzer for LNG

- EN

Application Note AN016

Questionnaires/Requirement Sheets

-

Questionnaire_PL AMS_PAT

Data Sheets

-

BENKE Vapor Pressure Process Analyzer RVP-4

Brochures

-

BENKE Vapor Pressure Process Analyzer RVP-4 Brochure