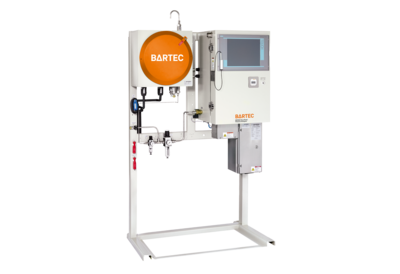

Freeze/Cloud Point Process Analyzer

Benefits

- ASTM compliant optical measurement

- Suitable to also measure cloud point temperature

- Typically no chiller required for cloud point applications

- Network and fieldbus communication

Marking

ATEX: II 2G Ex h IIC T4 Gb X

IECEx: Ex IIC T4 Gb

NEC 500: Class I, Division 2, Group B,C and D

NEC 505: Class I, Zone 1, AEx d e ib px IIB

resp. IIB+H2 T3 resp. T4

CEC Sec. 18: Ex d e ib px IIC T3 resp. T4

TR CU: II Gb T4 X

Ambient Temperature

T4Description

To remain competitive, today’s refiners must employ all optimization and product control techniques available. The use of online physical property analyzers is one of the key features to reach those objectives because they measure directly important quality properties in the process.

The freezing point as well as the cloud point are both important cold properties which need to be monitored by operators. A matter of fact is that cloud point and freezing point can be detected with one analyzer as the principle of detection is identical. The difference between the two properties is defined by the actual sample behavior. The sample e.g. gasoil is cooled down and below a certain limit small crystals start to appear, which results in a certain degree of cloudiness of the sample. At that point the so called Cloud Point temperature is determined via reduction of light intensity through an optical path. The cooling process is stopped and the crystals dissolve again. At that point the sample becomes clear and transparent again. As soon as all crystals have dissolved the so called Freezing Point temperature has been reached.

Technical Data

| Technology | optical turbidity detection |

|---|---|

| Method | compliant with: ASTM D2386, ASTM D1015, DIN ISO 3013, ASTM D7153-05, ASTM D7154-05, ASTM D2500 |

| Sample at inlet | filtered 50 μm, free of suspended water (≤ 37 cSt at inlet temperature) approx. 5 to 30 l/h 2 to 3 bar (29 to 43.5 psi) 5 to 15 °C (41 to 59 °F) min. 15 K above expected cloud point temperature |

| Sample at outlet | atmospheric pressure |

| Electrical data | max. 8 (4 to 20 mA; 1000 Ω); active isolated on request 4 to 20 mA; 160 Ω 24 V DC; max. 0.5 A high: 15 to 28 V DC; low: 0 to 4 V DC 24 V DC; max. 0.8 A |

| Communication | MODBUS/RTU via RS485 or RS422 or FOC is MODBUS/TCP via FOC is freezing point temperature, cloud point temperature, (others on request) Alarm, Ready signal, see options Stream Selection, Validation Request, Reset via Ethernet (VDSL or FOC is) |

| Ambient conditions | operation 5 to 35 °C (41 to 95 °F) storage -20 to 60 °C (-4 to 140 °F) operation 5 to 80 % relative humidity, non-corrosive; storage 5 to 80 % relative humidity, non-corrosive IP 54 (comparable with NEMA 13) |

| HMI | touch display 19" remote access on request cyber security operating system Windows10 enterprise LTSB Bartec Benke control software PACS |

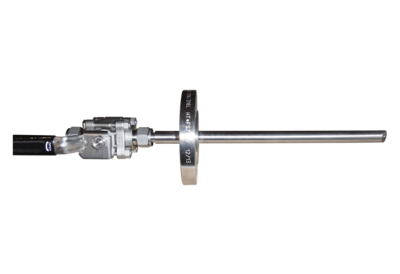

| Process connections | tube fittings: typically Swagelok 6mm/12mm/18mm; others on request sample inlet up to 2 sample streams and 1 validation stream sample outlet vent line (if required) coolant (if required) |

| Weight and dimensions | approx. 380 kg (without options) approx. 1140 x 2050 x 710 mm free space right: 160 mm/left: 390 mm |

Questionnaires/Requirement Sheets

-

Questionnaire_PL AMS_PAT

Data Sheets

-

BENKE Freeze/Cloud Point Process Analyzer FRP-4/CPA-4