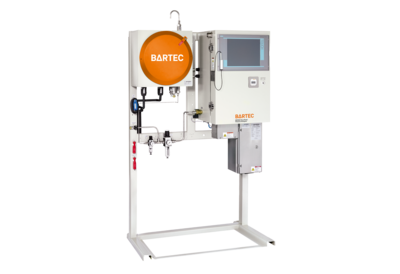

Sample Conditioning System

Benefits

- Sample rotameter with low flow contact

- Sample rotameter with a needle valve for water

- T-filter

- By-pass arrangement for T-filter

- Blow back system for T-filter

- Blind flanges

- Needle valve

- (See Description)

Marking

-

Ambient Temperature

-Description

Proper oil sampling is extremely important to an effective oil analysis. We need a representative oil sample to enable effective monitoring of the oil condition for the analyzers. The sample needs to fulfill certain criteria as cleanliness and dryness of the oil. To make sure obtaining a representative oil sample, we want to achieve the following: the sample should be extracted so that the information is uniform, consistent and representative. It is important that the sample does not become contaminated during the sampling process. We want to minimize data disturbance.

We offer a sample conditioning system that prepares high quality samples according to technical requirements. This will give you more accurate, consistent and useful samples. We offer a proper sampling procedure that helps to save time and money.

Our sample conditioning system includes:

- Sample rotameter with low flow contact

- Sample rotameter with a needle valve for water

- T-filter

- By-pass arrangement for T-filter

- Blow back system for T-filter

- Blind flanges

- Needle valve

- Coalescer Filter (self cleaning via bypass)

- Pressure regulator

- Laboratory sample take off

- Sample inlet/outlet pressure gauges

- Maintenance valves

- Safety relief valve

- Ball valves

- Heat exchanger

- Temperature gauge inside cabinet (range: 0 oC to 60 oC)

- Junction boxes (Material: GRP)