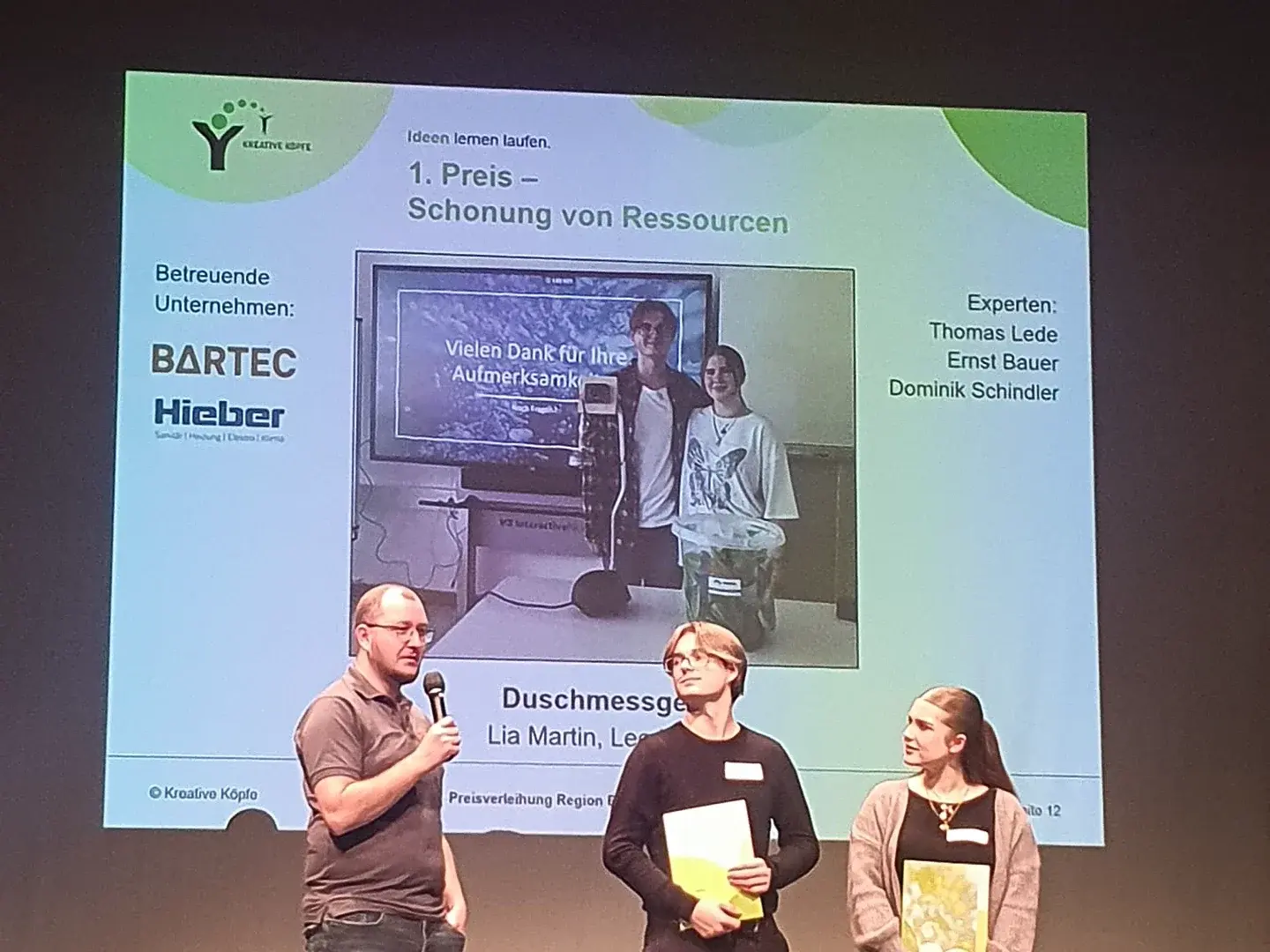

Creative Minds 2024: BARTEC Supports Next Generation of STEM Innovators to Success

For two decades, "Kreative Köpfe" (Creative Minds) has been motivating students to follow their inventiveness and spirit of discovery. Students between the ages of 13 and 18 who are enthusiastic about STEM (Science Technology Engineering Mathematics) can take part in the competition organized by the “Junge Kreative Köpfe” foundation and implement their project ideas with the support of experts from local companies. As a sponsoring company, BARTEC has been involved from the very beginning – and for this year´s 21st anniversary we were happy to support three great projects at our company.