What is a Megger test

The Megger test is a method of testing that assesses the insulation resistance, which relays the integrity of electrical insulation between core conductors and a ground reference. A low insulation resistance indicates voltage leakage, damage to the trace heater, and possible insulation faults. Failure to regularly conduct a Megger test could result in tripping of circuit breakers, electrical shock, or even a fire if the damage to an electrical system remains undetected for too long.

Megger test for electric heat trace cable installation

For heat trace cable installations, it's recommended to conduct the Megger test a minimum of four times throughout the installation phases. The preliminary test begins at the receipt of the cable (while still on the reel). This is in order to ensure that the cable was not damaged during transport or storage. Then comes the acceptance test (after the trace heater installation and before thermal insulation), which is carried out to check for possible damage occurring during installation. The final inspection test must be completed immediately after the thermal insulation installation to make certain no humidity or dust has negatively affected the cable. Lastly, test the insulation resistance of the cable before energizing the system. Branch circuit wiring can be included in the Megger test procedure by performing the test at the de-energized panel as well.

If a cable reel has been stored for an extended period, it is recommended to conduct another Megger test before the cable is installed on any construction site, as humidity and temperature may have affected the cable during storage.

Steps to perform a Megger test

Only properly trained personnel should perform the insulation resistance test.

In the video above, we at BARTEC conduct a Megger test on BARTEC's self-regulating HSB heating cable.

In preparation for the measurement, use the appropriate personal protective equipment (PPE), follow all safety guidelines, and, if applicable, de-energize the heating circuit.

We will start the preliminary test with a cable still on the reel, which consists of four steps:

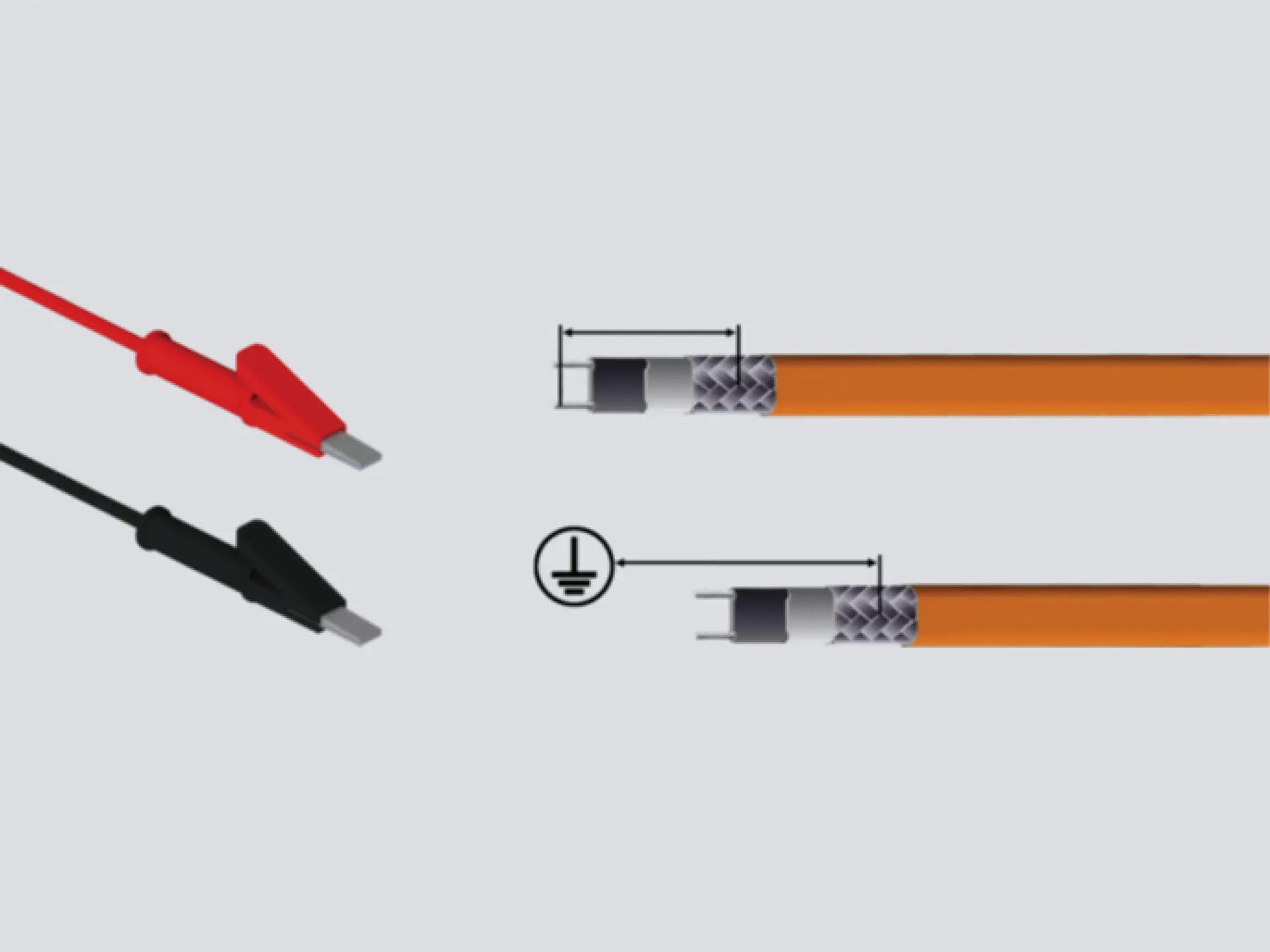

- Step 1: Safely strip the cable exposing the conductors.

- Step 2: Connect one of the test leads to the grounding braid and the other test lead to both bus wires.

- Step 3: Perform the insulation resistance test for one minute with a voltage of at least 500 VDC. We recommend testing at higher voltages such as 1000 VDC or 2500 VDC. A passing test should be at a minimum of 20 MΩ. We recommend values higher than 1000 MΩ. Rapid fluctuations of the Megohm value during the Megger test procedure may indicate an issue with the electrical circuit, e.g. the breakdown of the insulation.

- Step 4: Record the test values. This cable is now ready to be installed.

After installation, the acceptance test requires six steps:

- Step 1: Open the power termination kit cover and disconnect wires from the terminals with the appropriate tools. If installed, also disconnect any thermostat or controller.

- Step 2: Connect one of the test leads to the grounding braid and the other test lead to both bus wires.

- Step 3: Perform the insulation resistance test for one minute with a voltage of at least 500 VDC. We recommend testing at higher voltages such as 1000 VDC or 2500 VDC. A passing test should be at a minimum of 20 MΩ. We recommend values higher than 1000 MΩ. Rapid fluctuations of the Megohm value during the Megger test procedure may indicate an issue with the electrical circuit, e.g. the breakdown of the insulation.

- Step 4: Repeat the insulation resistance test between the grounding braid and the grounded workpiece. The reading should be similar to the one measured between the grounding braid and the bus wires.

- Step 5: Record the test values.

- Step 6: Re-connect the wires into terminals and close the cover on the power termination kit. If installed, reconnect any thermostats or controllers. Repeat steps one through five for your final inspection test and before energizing the system.

Typical results of Meg test

High resistance (hundreds of MΩ or more): Good insulation.

Low resistance (below manufacturer’s recommended threshold): Insulation is deteriorating or faulty.