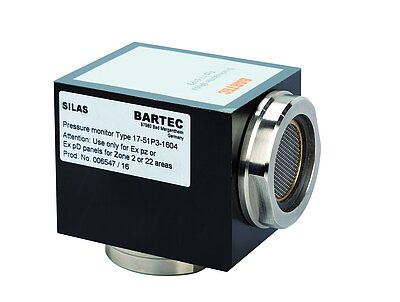

APEX (SILAS) Pressurized Cabinet

Benefits

- Customized Solutions

- Cabinets in stainless steel or sheet steel coated

- Ex p variants pxb, pyb and pzc

- Protected volume up to 17 m³

Marking

APC ATEX:

Ex II 2G Ex pxb/pyb * IIC T5 - T3 Gb

Ex II 2D Ex pxb/pyb * IIIC T95 °C - T130 °C Db

APC IECEx:

Ex pxb/pyb * IIC T5 - T3 Gb

Ex pxb/pyb * IIIC T95 °C - T130 °C Db

SPC ATEX:

Ex II 3G Ex pzc * IIC T5 - T3 Gc

Ex II 3D Ex pzc * IIIC T95 °C - T130 °C Dc

SPC IECEx:

Ex pzc * IIC T5 - T3 Gc

Ex pzc * IIIC T95 °C - T130 °C Dc

Ambient Temperature

Operating temperature-55 °C to +70 °C @ T4

(-67 °F to 158 °F @ T4)

depends on application

Storage temperature

-20 °C to +60 °C

(-4 °F to 140 °F)

Description

The need for complex automation functions for processes in the chemical, pharmaceutical, oil and gas sectors is constantly increasing.

Flexible, reliable and low-maintenance solutions are required for measurement, control, regulation and visualisation, especially in potentially explosive atmospheres.

Complete control systems and switchgears, drives, pumps, large displays and industrial monitors, including keyboard and printer, must be prepared for use in Ex areas. The Ex p pressurised enclosure is one of the most flexible Ex solutions for many applications.

This type of ignition protection makes it possible to operate non-ex-capable devices in potentially explosive atmospheres in Zones 1/21, 2/22. The idea behind this is to prevent a potentially explosive atmosphere from entering a sealed protective housing by generating constant overpressure compared to the surrounding atmosphere.

BARTEC offers an Ex solution for controlling and automating devices, machines and systems in Zones 1/21, 2/22 in the form of the pressurised enclosure Ex p systems. Depending on the application, non-Ex-protected control units and switching devices, as well as complete automation systems, are installed in the housing. Modern, ready-for-operation Ex solutions – including the required ATEX or IECEx certification – are created on the basis of BARTEC‘s modular, ATEX-certified pressurised enclosure. The overpressure as a result of the purge gas is produced by compensating for the leakage losses. The pressurised enclosure solution is designed for a large range of ambient temperatures in temperature classes T3 to T5.

The main focus is on maintenance and availability of Ex devices and systems. The experts at BARTEC have many years of experience in explosion protection applications and in designing complete systematic solutions for automation. This expertise is the basis for developing reliable and efficient solutions, from engineering, manufacturing and procurement, through to commissioning and approval.

The Ex p solutions are designed from sheet steel or stainless steel, with air conditioning, with different coatings, seawater-resistant or drip-resistant, depending on the application.

Customized Solutions

BARTEC offers customized, pressurized solutions for:

- Devices

- Printers

- Operator terminals

- Control units

- Frequency converters

- Monitors

Air-conditioning

Optionally available from BARTEC various solutions to the climate of Ex-p systems:

- Operating heating

- Standstill heating

- Air cooler

- Air-conditionier

- Water-air cooler

Technical Data

| Protection class | Up to IP 66 acc. EN(IEC 60529 (Applikationsabhängig) ≥ IP 4x acc. EN/IEC 60079-0 |

|---|---|

| Dimensions | Protected volume: max. 17300 dm³ |

| Material | Stainless steel, coated sheet steel Die-cast aluminium, plastic (separately certified) |

| Pressure | Pressure range: 0 to 25 mbar Purge gas pre compression: 1 bis 25 bar Operating pressure: 2 bis 4 mbar Purge pressure: 1 bis 20 mbar |

| Purging time | 0 to 120 Minutes |

| Rated voltage | max. 10 kV |

| Rated current | max. 10 kA |