Pour Point Analyzer

Model P-840LT

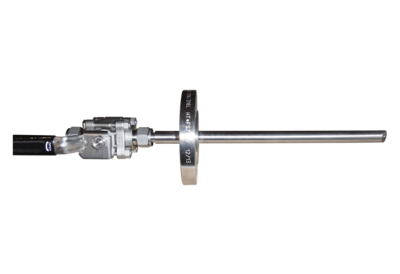

P-840LT-1.00

Benefits

- Operating range -100 to 25 °C (-148 to 77 °F)

- Rapid analysis cycles of 10 to 45 minutes

- Superior repeatability of less than 0.5°F (0.25°C)

- High pressure sample detection cell eliminates the need for atmospheric recovery

- Stream switching and validation

- Remote diagnostics over IP

Description

To remain competitive, today’s refiners must employ all optimization and product control techniques available. The use of online physical property analyzers is one of the key features to reach those objectives because they measure important quality properties in the process directly. The no flow point (correlating to pour point) is the temperature where a product (as it is cooled) stops flowing.

Technical Data

| Technology | Differential pressure sensing system |

|---|---|

| Method | Compliant with ASTM D7346 Correlates with ASTM D97 |

| Measuring cycle | Typical is less than 20 minutes |

| Analog outputs | Pour Point/No Flow Point, cell temperature, pressure signal |

| Digital outputs | Pour point alarm, analyzer fault, come read (programmable) |

| Digital inputs | customer alarm, remote standby, stream switch, validation (dry contact) |

| Display | 7" color graphics |

| Weight | approximately 340 kg (750 lbs) |

| Dimensions | Approximately 940 x 1803 x 762 mm (37 x 71 x 30 inches) |

| MODBUS interface | TCP/IP or Serial/RTU MODBUS output available |

Manuals/Operating Instructions/Guides

-

User Manual P-840LT

Data Sheets

-

Pour Point Anayzer Model P-840LT Specifications

Brochures

-

Pour Point Analyzer Model P-840LT Brochure