Explosion protection principles

Protection principles are defined to prevent equipment and components becoming ignition sources.

The protection principles can be applied to;

- electrical

- non-electrical equipment

- gases

- dusts

In industrial settings, in hazardous areas like those found in oil & gas, chemical, or pharmaceutical industries, equipment is classified as either electrical or non-electrical based on whether it uses electricity to function.

Electrical equipment in hazardous areas

Electrical equipment refers to devices that operate using electrical power. These components can generate sparks or heat, which is why they must be specially designed for use in explosive atmospheres.

Examples of electrical equipment are:

- Control panels

- Lighting fixtures

- Power distribution boxes

- Human Machine Interfaces (HMI)

Explore BARTEC electrical equipment below.

The principles allow for a design in various safety categories in accordance with the ATEX Directive 2014/34/EU (ATEX Blue Guide) or the Equipment Protection Level (EPL) according to EN / IEC 60079 series:

Equipment category 1 | Very high level of protection and thus a very high degree of safety. |

| Equipment category 2 | High level of protection and therefore a high degree of safety. |

| Equipment category 3 | Normal level of protection and therefore a conventional degree of safety. |

| Equipment level of protection a | Very high level of protection and thus a very high degree of safety. |

| Equipment level of protection b | High level of protection and therefore a high degree of safety. |

| Equipment level of protection c | Normal level of protection and therefore a conventional degree of safety. |

Ignition sources which are caused by sparks from friction or impact or from electro-static charging have to be prevented in explosion protected equipment by selecting appropriate materials and by constructive measures, and this must be verified and confirmed by appropriate tests.

There are different protection principles which can prevent equipment from becoming an ignition source.

An important precondition for all the protection principles is that parts which are in unhindered contact with the explosive atmosphere must not be able to reach non-permitted temperatures with respect to the ignition temperature of substances present in the site of installation. This means that the ignition temperature is relevant for all protection principles.

1. Explosive mixtures can enter the equipment in which an ignition source may be located and be ignited. The transmission of internal ignition to the surrounding atmosphere shall be excluded.

Examples of types of protection:

2. The operating equipment has an enclosure which prevents the penetration of the explosive mixture and/or contact with the internal function-related potential sources of ignition.

Examples of types of protection:

- Pressurized enclosures (Ex p)

- Protection by enclosures (Ex t)

- Liquid immersion (Ex o)

- Encapsulation (Ex m)

3. Explosive mixtures can penetrate the enclosure of the operating equipment but is not allowed to be ignited. Any spark is prohibited and temperatures capable of causing ignitions shall be prevented.

Examples of types of protection:

4. Explosive mixtures can penetrate the enclosure of the operating equipment but can’t be ignited. The occurrence of spark energy and increased temperatures shall be limited.

Examples of types of protection:

5. Optical radiation is used but it is prevented to cause an ignition.

There are three different types:

- Ex op is: Inherently safe optical radiation

- Ex op pr: Protected optical radiation

- Ex op sh: Optical system with interlock

It applies to all types of protection where parts that are in unhindered contact with the explosive atmosphere are not permitted to reach unacceptably high temperatures.

Taking into account both the environmental temperature and the heating effect, the temperature may attain maximum values which corresponds to the temperature class or the permissible temperature specified for flammable dusts in accordance with which the explosive atmosphere has been classified.

Types of explosion protection of electrical equipment

Protection principles | Types of protection | Flammable | Category 1 | Category 2 | Category 3 |

|---|---|---|---|---|---|

| Very high level of protection | High level of protection | Normal level of protection | |||

All | General requirements | Gas/vapour (G) | + | + | + |

| Protection principle ensures that an ignition source cannot arise. | Increased safety Ex e | Gas/vapour (G) | - | Ex eb | Ex ec |

Optical radiation interlocked with Ex op EN IEC 60079-28 | Gas/vapour (G) dust (D) | - | Ex op sh | + | |

| Protection principle prevents an ignition source becoming effective. | Intrinsic safety EN IEC 60079-11 | Gas/vapour (G) dust (D) | Ex ia | Ex ib | Ex ic |

Inherently safe optical radiation EN IEC 60079-28 | Gas/vapour (G) dust (D) | Ex op is | + | + | |

| Protection principle prevents the potentially explosive atmosphere reaching the ignition source. | Encapsulation EN IEC 60079-18 | Gas/vapour (G) dust (D) | Ex ma | Ex mb | Ex mc |

Non incendive Ex nC EN IEC 60079-15 | Gas/vapour (G) | - | - | Ex nC Ex nR | |

Liquid immersion EN IEC 60079-6 | Gas/vapour (G) | - | Ex ob | Ex oc | |

Pressurised enclosure EN IEC 60079-2 | Gas/vapour (G) dust (D) | - | Ex pxb, pyb | Ex pzc | |

Protection by enclosure Ex t EN IEC 60079-31 | Dust (D) | Ex ta | Ex tb | Ex tc | |

Protected optical radiation EN IEC 60079-28 | Gas/vapour (G) dust (D) | - | Ex op pr | + | |

| Protection principle prevents propagation of flames using an enclosure. | Flameproof enclosure EN IEC 60079-1 | Gas/vapour (G) | Ex da | Ex db | Ex dc |

Powder filling EN IEC 60079-5 | Gas/vapour (G) | - | Ex q | + | |

| Table 5 + means: possible to apply - means: NOT possible to apply. | Apllication in hazardous areas, depending either G or D | ||||

| Zone 0/20 | Zone 1/21 | Zone 2/22 | |||

| Zone 1/21 | Zone 2/22 | ||||

| Zone 2/22 | |||||

Types of explosion protection of non-electrical equipment

Protection principles | Types of protection | Flammable | Category 1 | Category 2 | Category 3 |

|---|---|---|---|---|---|

| Very high level of protection | High level of protection | Normal level of protection | |||

All | General requirements | Gas/vapour (G) | + | + | + |

| Protection principle ensures that an ignition source cannot arise. | Constructional safety c EN ISO 80079-371) | Gas/vapour (G) dust (D) | Ex h | Ex h | Ex h |

| Protection principle prevents an ignition source becoming effective. | Control of ignition source b EN ISO 80079-371) | Gas/vapour (G) dust (D) | Ex h | Ex h | Ex h |

| Protection principle prevents the potentially explosive atmosphere reaching the ignition source. | Liquid immersion k EN ISO 80079-371) | Gas/vapour (G) dust (D) | Ex h | Ex h | Ex h |

| Pressuries enclosure EN IEC 60079-22) | Gas/vapour (G) dust (D) | - | Ex pxb, pyb | Ex pzc | |

| Flow restricting enclosure EN 13463-2 | Gas/vapour (G) | - | - | fr | |

| Protection by enclosure EN IEC 60079-312) | Dust (D) | Ex ta | Ex tb | Ex tc | |

| Protection principle prevents propagation of flames using an enclosure. | Flameproof enclosure EN 13493-3 EN IEC 60079-12) | Gas/vapour (G) | - - | d Ex db | + Ex dc |

Table 6 1) The EN ISO 80079-36 and -37 standards form in addition to the EN IEC 60079 series of standards a holistics set of technical standards for the development, testing and certification of explosion-proof-non-electrical equipment. + means: possible to apply | Apllication in hazardous areas, depending either G or D | ||||

| Zone 0/20 | Zone 1/21 | Zone 2/22 | |||

| Zone 1/21 | Zone 2/22 | ||||

| Zone 2/22 | |||||

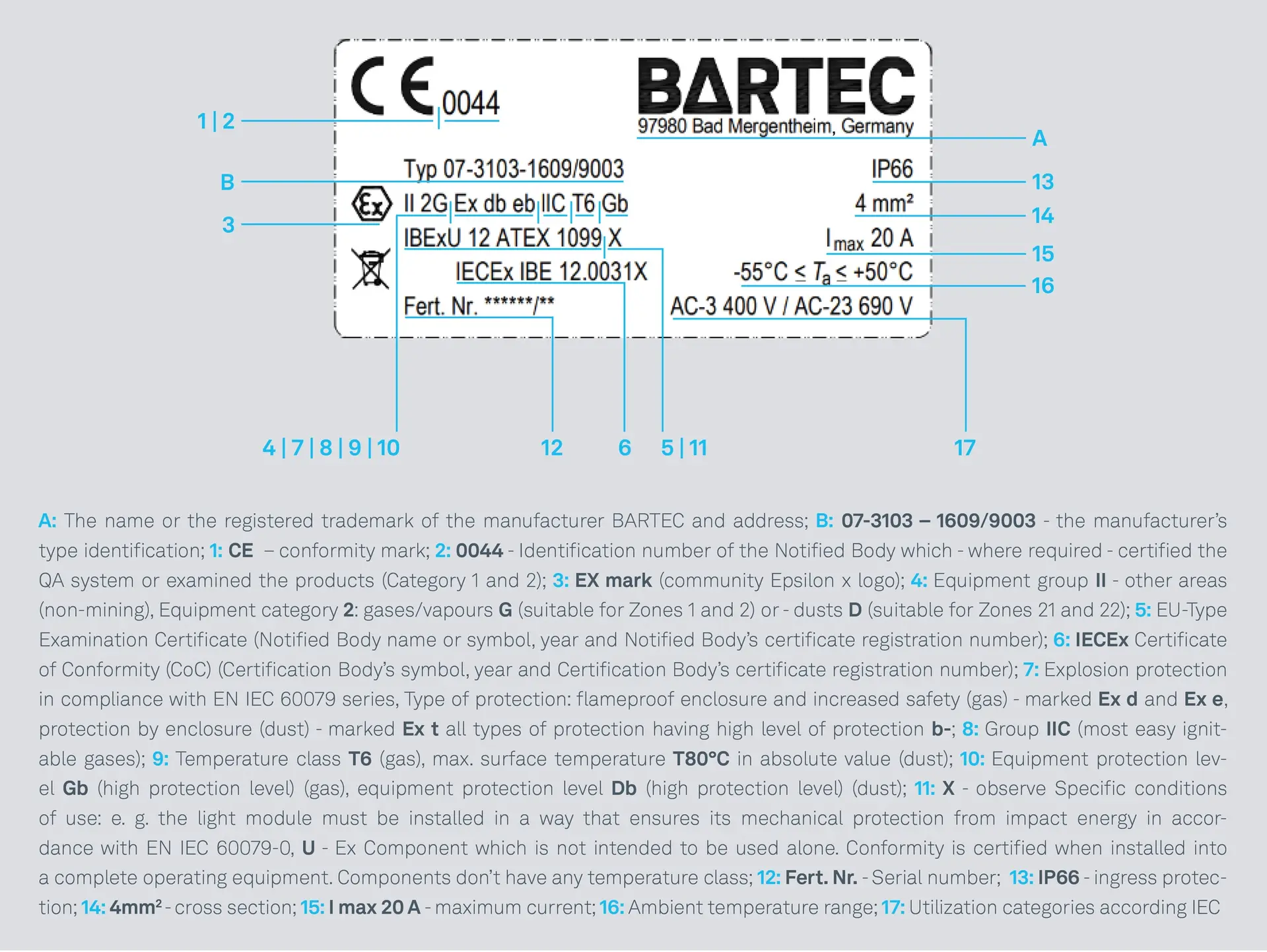

Marking of electrical equipment

Marking examples in accordance with ATEX directive 2014/34/EU according to EN 60079 series and IECEx System according to IEC 60079 series. Information specific to explosion protection (marking).