Learn about:

- What is a Dust Explosion?

- What are the Key Requirements for a Dust Explosion?

- Ignition Temperature of Dusts (Layer and Cloud)

- Equipment Sub-groups for Combustible Dusts

- Examples of the Assignment of Gases and Vapours to the Respective Temperature Classes and Explosion Sub-groups

- Prevention of Hazardous Dust Explosions

- Sources

- Frequently Asked Questions

What is a dust explosion?

A dust explosion is a rapid combustion of fine particles suspended in the air within an enclosed space. It occurs when a combustible dust, such as grain, coal, metal, or chemical powder, mixes with oxygen and is ignited by a heat source, for instance: a spark, flame, or hot surface. The explosion happens in two stages:

- Primary Explosion – The initial ignition of suspended dust, which creates a pressure wave.

- Secondary Explosion – The primary explosion disturbs more dust, leading to a much larger and more destructive explosion.

Any combustible material can burn rapidly when in a finely divided form. If such a dust is suspended in air in the right concentration, under certain conditions, it can become explosive. Even materials that do not burn in larger pieces (such as aluminum or iron), given the proper conditions, can be explosive in dust form.

What are the key requirements for a dust explosion?

Explosions from combustible dust are violent and often devastating events that occur when fine, dry particles of combustible materials and explosive dust, become suspended in air and then ignite, leading to a rapid release of energy, and a primary explosion.

Key elements necessary for such an explosion include fuel (the dust), oxygen (present in the air), and an ignition source (typically a spark, open flame, or even hot surfaces).

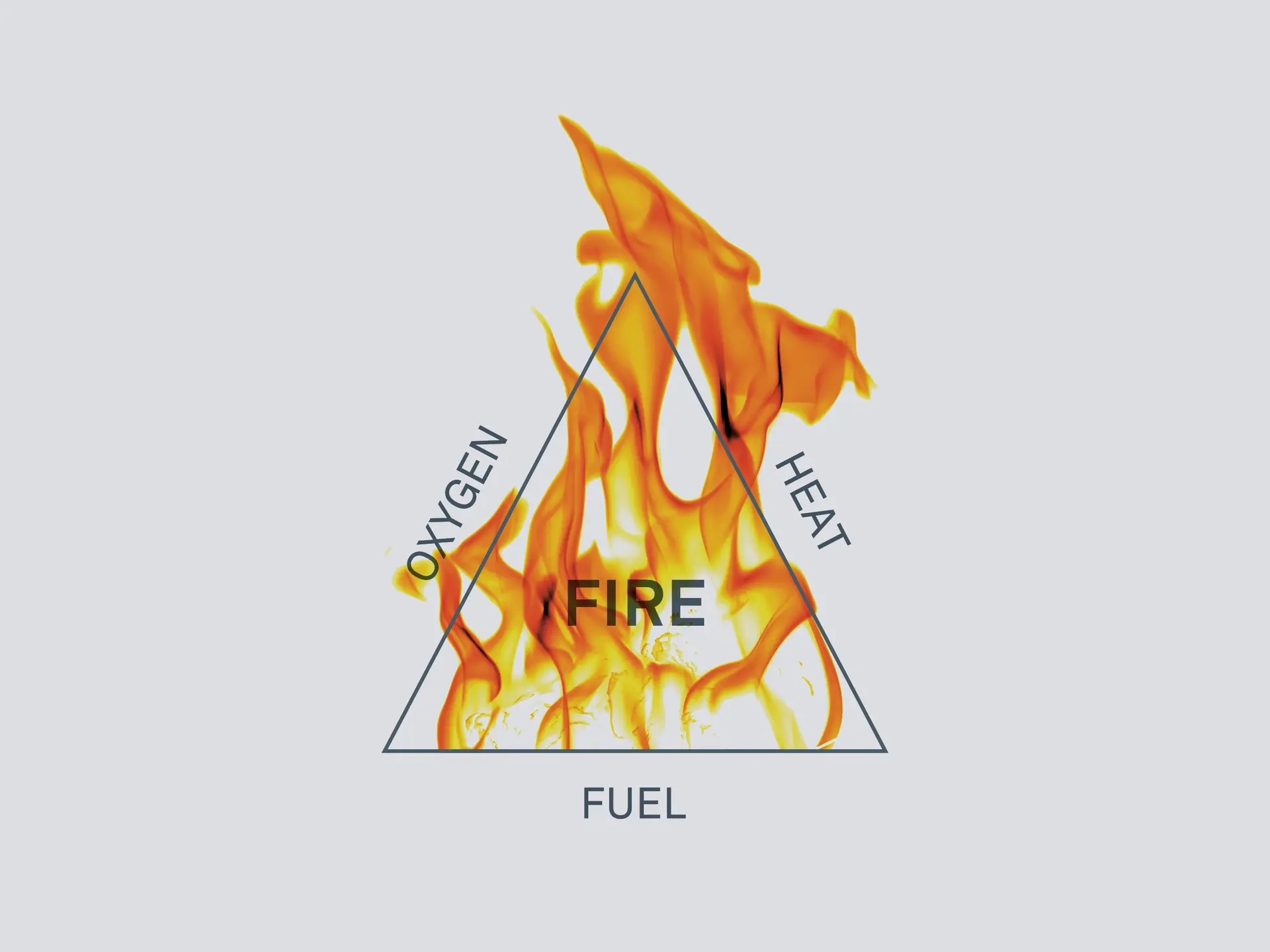

The fire triangle for dust explosion must have present three elements:

- Fuel – A combustible dust

- Oxygen – Sufficient air supply

- Ignition Source – Heat, sparks, or open flames

So if you have these three elements at the same time, in the right concentration, you get a fire which is essentially a dust explosion.

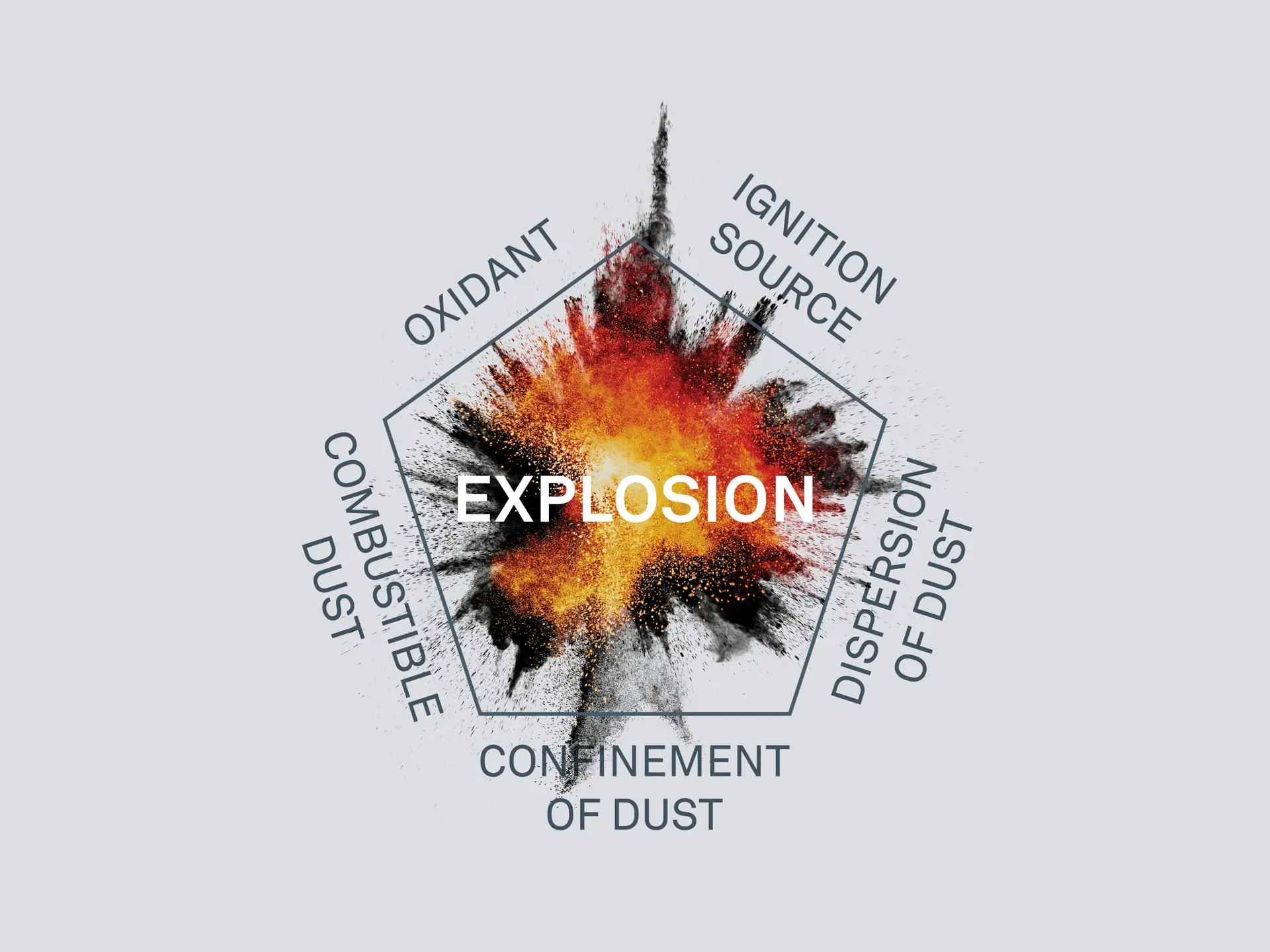

The dust explosion pentagon is an expansion of the fire triangle as it relates to combustible dust. For a dust explosion to occur, five elements must be present:

- Fuel – A combustible dust

- Oxygen – Sufficient air supply

- Ignition Source – Heat, sparks, or open flames

- Dispersion – Dust must be suspended in the air

- Confinement – A closed or semi-closed space to trap pressure

The sequence of events leading to an explosion involves the dispersion of combustible dust particles in the air, the formation of a dust cloud, ignition, and the subsequent rapid combustion of the combustible dust cloud, resulting in pressure waves, fireballs, and potential damage.

Ignition temperature of dusts (layer and cloud)

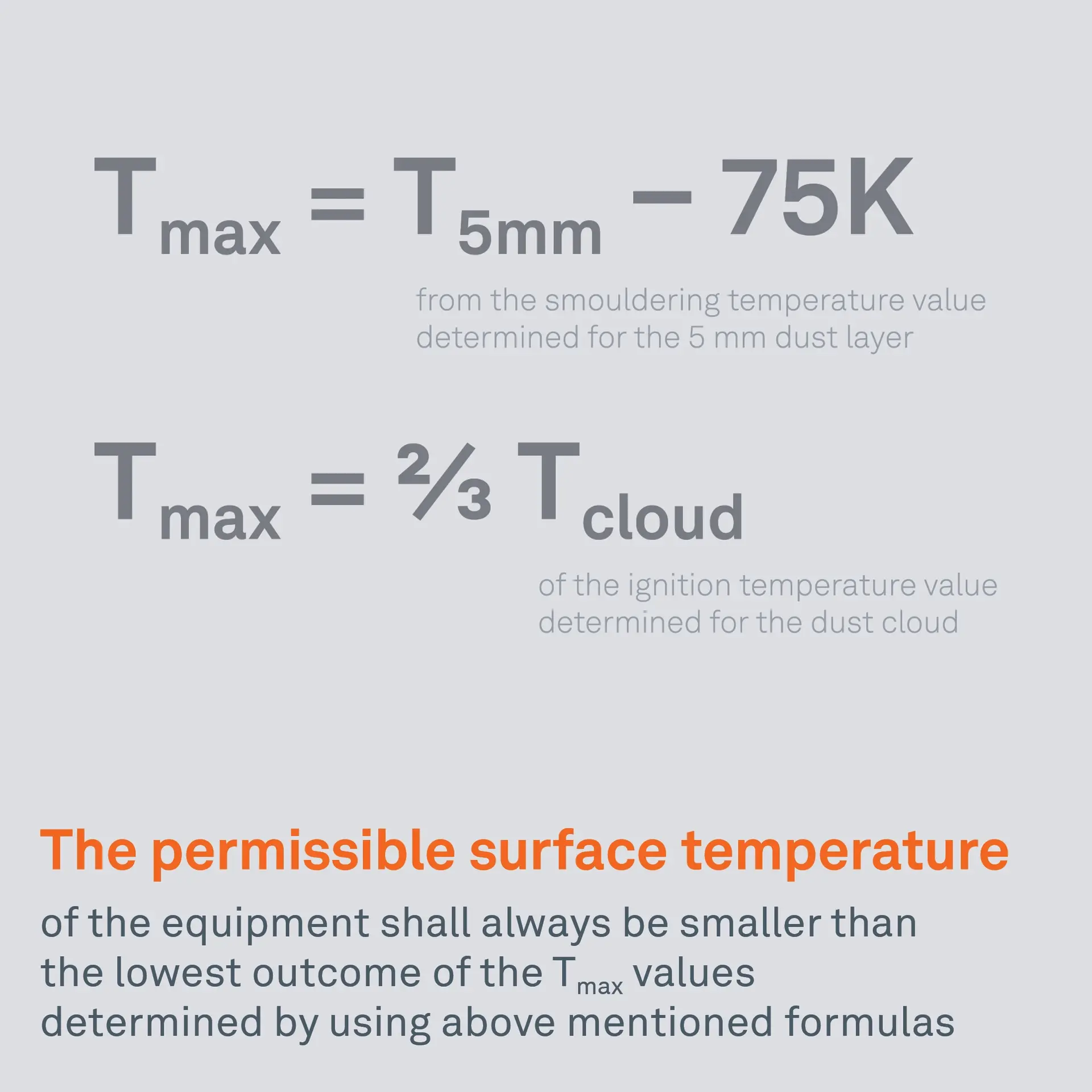

For different types of dust, the method for determining the ignition temperature has been unified and coded in document EN-ISO/IEC 80079-20-2. Please note that dust in its deposited form (layer) has a different ignition (read: smouldering) temperature than in its stirred form (cloud).

The permissible surface temperature for those parts of systems and equipment is determined by subtracting 75 K (Tmax = T5 mm - 75 K) from the smouldering temperature value determined for the 5 mm dust layer and by taking 2/3 (Tmax, = 2/3TCloud) of the ignition temperature value determined for the dust cloud.

The permissible surface temperature of the equipment shall always be smaller than the lowest outcome of the Tmax. values determined by using above mentioned formulas. Temperature classes are not defined for dust, so a concrete type of dust must always be considered. The parameters are made available in comprehensive tables, laboratories determine the values on request, and a small, non-official overview is contained in the downloadable brochure ‘basic concepts’ (edition 14).

Equipment sub-groups for combustible dusts

From the point of view of electrical engineering, it is not possible to classify dust as precisely as the chemically defined gases and vapours. For that reason, it is considered sufficient to divide the dust according to type and conductivity. EN-ISO/IEC 80079-20-2 contains the test method to determine the specific electrical resistance of dust. Dust is divided into 3 sub-groups:

- IIIA - combustible flyings

- IIIB - non-conductive combustible dust with electrical resistivity > 1 kΩ·m

- IIIC - conductive combustible dust, with electrical resistivity ≤ 1 kΩ·m

Take a look at the Groups classification of electrical safety equipment:

Group I

Equipment intended for use in mines susceptible to firedamp (flammable mixture of gases naturally occurring in a mine).

Group II

Equipment intended for use in areas with an explosive gas atmosphere other than mines susceptible to firedamp. Group II equipment is subdivided into three sub-groups:

Group IIA—Atmospheres containing propane.

Group IIB—Atmospheres containing ethylene.

Group IIC—Atmospheres containing hydrogen or acetylene.

Group III

Equipment intended for use in areas with an explosive dust atmosphere other than mines susceptible to firedamp. Group III equipment is subdivided into three sub-groups:

Group IIIA—Atmospheres containing combustible flyings.

Group IIIB—Atmospheres containing non-conductive dust.

Group IIIC—Atmospheres containing conductive dust

Examples of the assignment of gases and vapours to the respective temperature classes and explosion sub-groups

| Designation of the solid material | Ignition temperature EN-ISO/IEC 80079-20-2 T5 mm layer (°C) | Ignition temperature EN-ISO/IEC 80079-20-2 TCloud (°C) | Permissible surface temperature of the equipment lowest value of the calculation (T5 mm layer - 75 K) and 2/3*TCloud | |||||||||

| > 300 ...450 | > 280 ...300 | > 260 ...280 | > 230 ...260 | > 215 ...230 | >200 ...215 | > 180 ...200 | > 165 ...180 | > 160 ...165 | > 135 ...160 | |||

| Dust from natural materials (examples) | ||||||||||||

| Cotton | 350 | 560 | 275 | |||||||||

| Brown coal | 225 | 380 | 150 | |||||||||

| Cellulose | 370 | 500 | 295 | |||||||||

| Cereals | 290 | 420 | 215 | |||||||||

| Sawdust (wood) | 300 | 400 | 225 | |||||||||

| Cocoa | 460 | 580 | 385 | |||||||||

| Cork | 300 | 470 | 225 | |||||||||

| Fooder concentrate | 295 | 525 | 220 | |||||||||

| Milk powder | 340 | 440 | 265 | |||||||||

| Paper | 300 | 540 | 225 | |||||||||

| Soya | 245 | 500 | 170 | |||||||||

| Starch | 290 | 440 | 215 | |||||||||

| Hard coal | 245 | 590 | 170 | |||||||||

| Tobacco | 300 | 450 | 225 | |||||||||

| Tea | 300 | 510 | 225 | |||||||||

| Wheat floor | 450 | 480 | 320 | |||||||||

| Dust of chemical technical products (examples) | ||||||||||||

| Cellulose ether | 275 | 330 | 200 | |||||||||

| Isosorbide dinitrate | 240 | 220 | 146 | |||||||||

| Unvulcanised rubber | 220 | 460 | 145 | |||||||||

| Petroleum coke | 280 | 690 | 205 | |||||||||

| Polyvinyl acetate | 340 | 500 | 265 | |||||||||

| Polyninyl chloride | 380 | 530 | 305 | |||||||||

| Soot | 385 | 620 | 310 | |||||||||

| Laminated plastic | 330 | 510 | 255 | |||||||||

| Sulphur | 280 | 280 | 186 | |||||||||

| Metal dust (examples) | ||||||||||||

| Aluminium | 280 | 530 | 205 | |||||||||

| Bronze | 260 | 390 | 185 | |||||||||

| Iron | 300 | 310 | 206 | |||||||||

| Magnesium | 410 | 610 | 335 | |||||||||

| Manganese | 285 | 330 | 210 | |||||||||

Find here more about the hazardous zone classification.

Prevention of hazardous dust explosions

Combustible dust hazards remain a significant concern in the modern life.

A wide range of industries, including oil and gas, pharmaceuticals, energy, chemical processing, generate dust as a byproduct of their operations. These industries face the ongoing challenge of managing the risks associated with dust.

To address the hazards associated with combustible dust, regulatory bodies worldwide have established safety standards and guidelines. In the United States, the Occupational Safety and Health Administration (OSHA) and the National Fire Protection Association (NFPA) provide industry-specific regulations, including NFPA 652, which outlines best practices for explosion prevention and mitigation. Similarly, in Europe, the ATEX directives govern the safe handling of explosive atmospheres, ensuring compliance with strict safety measures to protect workers and facilities, whereas IECEx, the IEC System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres provides a global system of approved certification bodies.

The prevention of explosions is a critical safety concern in various industries, and modern innovations have introduced a range of tools and technologies to address this issue. To reduce the risk of dust explosions, industries implement strict safety measures.

Prevention Measures:

- Dust control – Regular cleaning to prevent accumulation

- Proper ventilation – Reduce dust concentration in the air

- Explosion-protected equipment – ATEX-rated or IECEx-certified devices

- Ignition control – Avoid static electricity, sparks, and high heat

- Monitoring & detection – Sensors for early detection of hazardous dust level

- Equally important as technology is the training of personnel to recognize and address dust hazards. Proper training and education are key components of prevention.

BARTEC is the leading manufacturer of equipment designed to prevent dust explosion and users can choose from an array of products based on their need. Some of the most popular products are featured in the carousel below.