Explanation and Relevance of Hazardous Area Classification in Workplaces

In the blog, written by Steinar Grøndal, BARTEC Vice President Quality & Certification you will find the following topics explained:

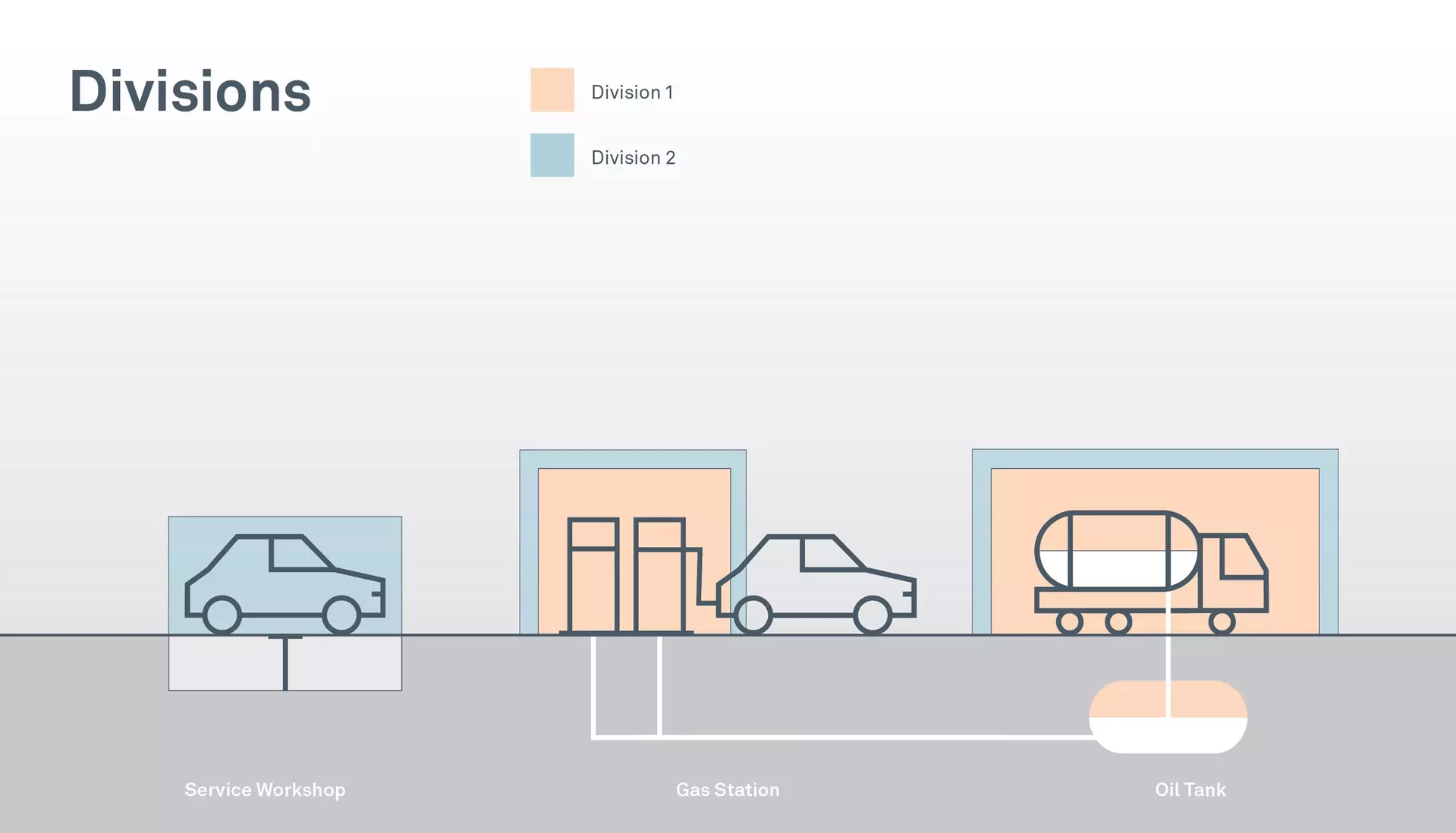

What is a hazardous area

A hazardous area is defined as an area in which an explosive atmosphere is present, or can be expected to be present, in quantities such that special precautions for the construction, installation and use of equipment are required. An explosive atmosphere is defined as a mixture with air, under atmospheric conditions, of flammable substances in the form of gas, vapour, mist, or dust which, after ignition, permits self-sustaining propagation. When electrical equipment, and also non-electrical equipment is used in, around, or near an explosive atmosphere, there is always a possibility or risk that a fire or explosion might occur. Examples of hazardous areas include:

Hazardous area classification (HAC)

Hazardous area classification is used to define areas where special precautions for the construction, installation and use of equipment should be applied.

Currently there are two major systems used to classify hazardous areas; the Class/Division system and the Zone system. The Class/Division system is used predominately in the United States and Canada under NEC/CEC Standards, whereas the rest of the world generally uses the Zone system. The hazardous zone classification is used worldwide under IEC standards and their local versions, such as ATEX in Europe.

Most countries require that products intended for installation in hazardous areas are approved by a recognized authority or approval agency (governmental or independent) which that country has established by various laws, regulations, or codes. In Europe, European Committee for Electrotechnical Standardization (CENELEC) is providing the relevant standards.

All equipment intended for use in potentially explosive atmospheres must comply with the current ATEX Directive 2014/34/EU for the EU, or IECEx for other countries.

Hazardous areas classification charts

The classification of Zones and Divisions is related to the frequency and duration that flammable gases or dusts may be present in the atmosphere. Hazardous locations per the Zone system are classified according to its Zone which can be gas or dust. For gas atmospheres electrical equipment is further divided into Groups and Subgroups.

ATEX Zone defines the probability of the flammable material, gas or dust, being present in sufficient quantities to produce explosive or ignitable mixtures. This classification takes the different dangers from explosive atmospheres into account and allows explosion protection measures to be taken which reflect the situation both from the point of view of safety engineering and of economic efficiency. For the European community, the hazardous zone classification and hazardous area zone classification charts definitions are uniformly provided in Directive 1999/92/EC (ATEX 153), also called the ‘Workplace Directive’ and the “Equipment Directive” Directive 2014/34/EU (ATEX 114) which must be applied with technical understanding of the specific situation.

Under the “Zone” system, hazards are defined for gas as Zone 0, 1 or 2, with 0 as the highest hazard, and for dust as Zone 20, 21 or 22, with 20 as the highest hazard.

Under the “Division” system, hazards are defined for gas as Class I Division 1 or 2, with 1 as the highest hazard, and for dust as Class II Division 1 or 2, with 1 as the highest hazard.

Divisions for gas, mist, or vapor

Class I, Division 1: The presence of combustible substances is continuous, frequent, or long-term

Class I, Division 2: The presence is unlikely and, if it occurs, is short-term

Divisions for dust:

Class II, Division 2: The presence of combustible substances is continuous, frequent, or long-term

Class II, Division 2: The presence is unlikely and, if it occurs, is short-term

In addition to Divisions, hazardous areas are categorized by the type of material present:

- Class I: Gases, vapors, or mists

- Class II: Combustible dusts

- Class III: Ignitable fibers or flyings

Gas Groups:

- Group A: Acetylene

- Group B: Hydrogen

- Group C: Ethylene

- Group D: Propane

Dust Groups:

- Group E: Metal dusts

- Group F: Carbonaceous dusts

- Group G: Grain dusts

Marking for equipment protection level (EPL)

Additionally, a marking for Equipment Protection Level (EPL) have been introduced:

| Substance | Duration of the Presence of the Combustible Substance | Zone | ATEX Categories (Levels of Protection) Group II | Level of Protection | EPL Code |

| Gas, mist, or vapour | Continuously for long periods or frequently | Zone 0 | 1G | Very High | Ga |

| Gas, mist, or vapour | Occasional occurrence | Zone 1 | 2G | High | Gb |

| Gas, mist, or vapour | Not likely, but if it occurs, it is only rarely and for a short period of time | Zone 2 | 3G | Normal | Gc |

| Substance | Duration of the Presence of the Combustible Substance | Zone | ATEX Categories (Levels of Protection) Group II | Level of Protection | EPL Code |

| Dust | Continuously for long periods or frequently | Zone 20 | 1D | Very high | Da |

| Dust | Occasional occurrence | Zone 21 | 2D | High | Db |

| Dust | Not likely, but if it occurs, it is only rarely and for a short period of time | Zone 22 | 3D | Normal | Dc |

Reference to the table.

Hazardous area zone classification chart

ATEX Zone classification for gases and vapours

ATEX Zone 0, EPL Ga

Zone 0 is an area in which an explosive gas atmosphere is present continuously, or for long periods, or frequently

ATEX Zone 1, EPL Gb

Zone 1 is an area in which an explosive gas atmosphere is likely to occur occasionally in normal operation

ATEX Zone 2, EPL Gc

Zone 2 is an area in which an explosive gas atmosphere is not likely to occur in normal operation, but, if it does occur, will exist for a short period only

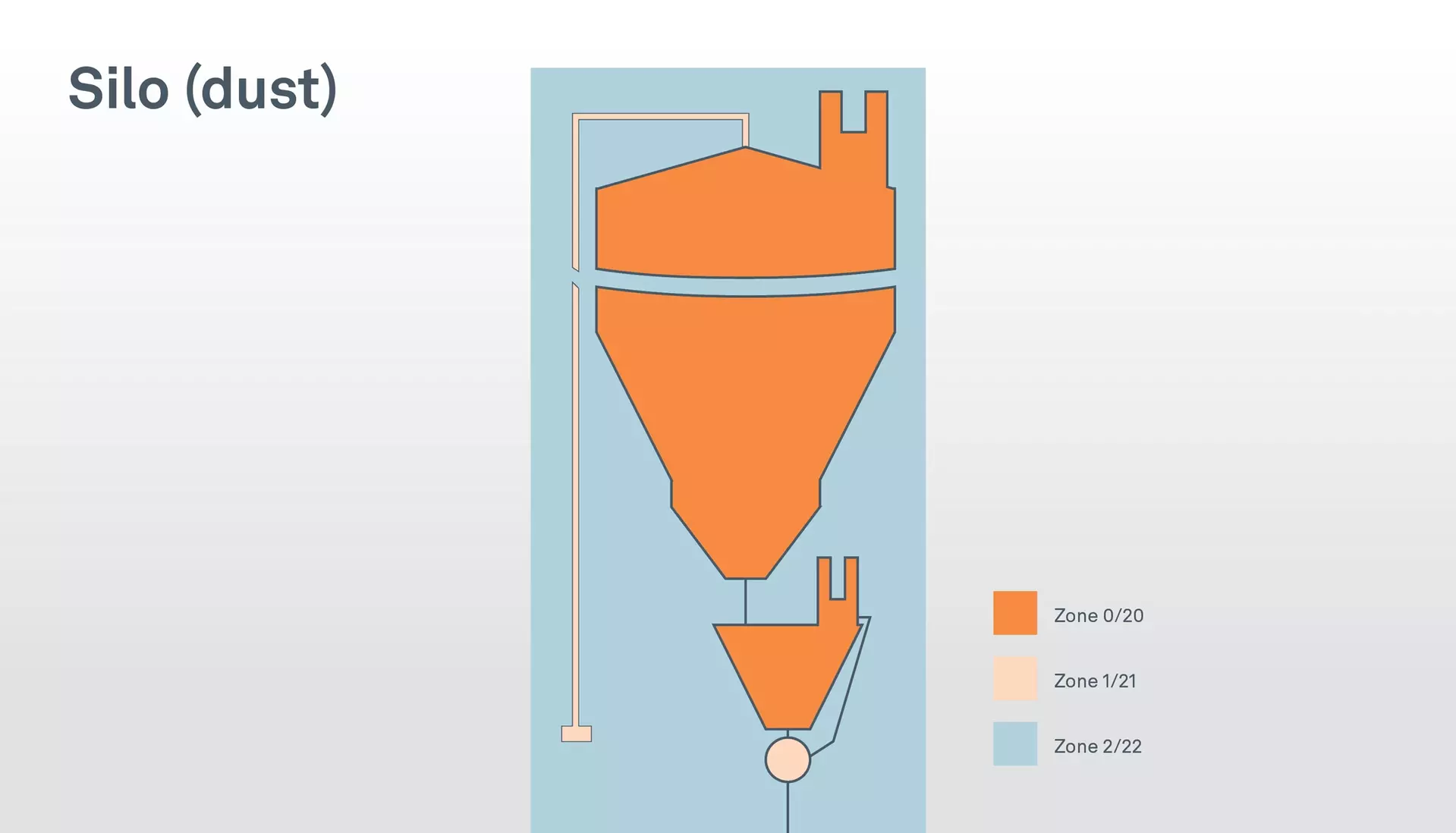

ATEX Zone Classification for Dust

ATEX Zone 20, EPL Da

Zone 20 is a place in which an explosive dust atmosphere, in the form of a cloud of dust in air, is present continuously, or for long periods or frequently

ATEX Zone 21, EPL Db

Zone 21 is a place in which an explosive dust atmosphere, in the form of a cloud of dust in air, is likely to occur in normal operation occasionally

ATEX Zone 22, EPL Dc

Zone 22 is area in which an explosive dust atmosphere, in the form of a cloud of combustible dust in air, is not likely to occur in normal operation but, if it does occur, will persist for a short period only

IEC 60079-10-1 assumes an approximately similar classification for flammable gases and vapours which will also apply to facilities constructed in accordance with the US standard NEC 505. IEC 60079-10-2 provides support for the zone classification with combustible dust and will also apply to facilities constructed in accordance with the US standard NEC 506.

Potentially explosive atmospheres are classified depending on the frequency and duration of the explosive atmosphere. This classification provides the scope of the measures to be taken according to Annex II section A in the Directive 1999/92/EC in conjunction with equipment categories according to Annex I of the Directive 2014/34/EU.

When the hazardous areas of a plant have been classified, the remainder will be defined as non-hazardous, sometimes referred to as 'safe areas'.

In workplaces the potentially explosive atmospheres are normally classified at most as Zone 1 or 2 and 21 or 22. Zone 0 and 20 are restricted to very small inaccessible areas in work places or are usually restricted to the inside of technical equipment.

Organizational measures for companies

The requisite preconditions for the safe operation of electrical equipment in hazardous areas are created in a joint effort by the manufacturers of explosion-protected equipment and the constructors, operators and owners of industrial plants. It is important that the operator and owners of such plants ensures that their personnel know how the danger of explosions, are aware of the hazardous area classification and understand the consequences that are likely to occur in the ATEX Zone 0, Zone 1, Zone 2 and the measures that are to be taken to prevent it.

The employees shall be regularly trained on the contents of the explosion protection document in accordance with the The ATEX Directive 1999/92/EC (occupational safety regulations) and informed by means of written corporate regulations which shall be regularly updated.

Factors to consider during inspection

If there are any large areas of zone 1 on the Hazardous Area Classification Drawings, if there is evidence that by design and operation controls, the sources of release and consequently the location and extent of hazardous areas have been minimised?

Do any zone 2 areas extend to places where the occupier has inadequate control over activities that could create an ignition source, or is there any suggestion that the zone boundaries have been arbitrarily adjusted to avoid this?

Has ignition protected equipment been installed and maintained by suitably trained staff.

Are the risks from static discharges controlled properly? Earthing of plant, drums and tanks is the most basic requirement.

What control measures over ignition sources are adopted in hazardous areas during maintenance; where ignition sources must be introduced, typical precautions include the use of supplementary ventilation, portable gas detectors, and inerting of sections of the plant.

- Layers, deposits and heaps of combustible dust shall be considered as any other source which can form an explosive atmosphere.

- ‘Normal operation’ means the situation when installations are used within their design parameters

- The definitions for explosive atmospheres comply with the European directives and EN-IEC standards:

- Explosive atmosphere: this is a mixture of air and flammable substances in the form of gases, vapours, mists or dusts under atmospheric conditions in which, after ignition has occurred, combustion spreads to the entire unburned mixture.

- Hazardous explosive atmosphere: this is an explosive atmosphere that causes damage on explosion, and which necessitates the introduction of measures to protect employees from explosion hazards.