Mining Electrical Motors

Benefits

- Highest degree of safety and reliability

- Certified for I M2 group

- Modular design, which allows execution of all IEC forms and different positions/rotations of connection box

- Certied for implementation of VICTOR sockets

- SWAN NECK motor execution is perfect solution for fan applications

- Ex db or Ex db eb cast iron or welded frame and connection box

- ATEX, IECEx, EAC ...

- Wide ingress protection range: IP55 up to IP66

- Suitable for Ambient Temperatures from -20°C to +40°C

Marking

ATEX:

I M2 Ex db I Mb

I M2 Ex db eb I Mb

IECEx:

Ex db I Mb

Ex db e I Mb

Ingress protection

Standard IP55

On request up to IP66

Ambient temperature

Standard -20 °C up to +40 °C

Ambient Temperature

Standard: -20 °C up to +40 °CDescription

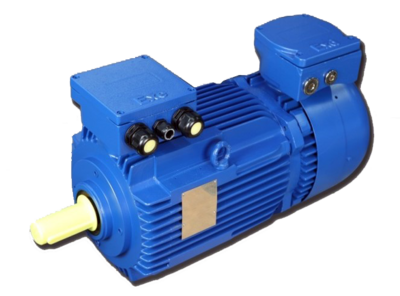

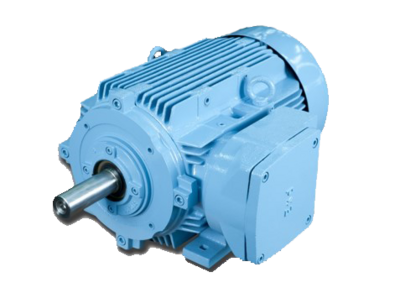

Electrical mining motors are robust, high-performance devices crucial for the mining industry. Designed to withstand harsh conditions, these motors power heavy machinery like drills, excavators, and conveyor systems, ensuring seamless operations in mines. With advanced technology, they offer superior efficiency, reliability, and safety, optimizing energy consumption while delivering high torque output. These motors are engineered for durability, often resistant to dust, moisture, and extreme temperatures. Their precision and power enable mining operations to be more productive, making them indispensable components in the mining sector's pursuit of efficiency and sustainability.

Technical Data

These are three-phase asynchronous electric motors with shot-circuit rotor, according to the EN 60079-0, EN 600079-1, EN 600079-7 and EN 60079-31 standards.

- Available in cast iron or welded housing

- Enclosure Ex db

- Enclosure Ex db eb

- Frame size 71 - 355

- Power up to 400 kW

Manuals/Operating Instructions/Guides

Declarations

Data Sheets

-

KTCR & KTCP range