Heating technology from BARTEC

As bitumen only remains liquid – and therefore conveyable – at certain storage temperatures of up to +180 °C, electric trace heating plays a vital role. In order to avoid both functional and economic risks, client Caspi Bitum called upon BARTEC's expertise. The challenge was to complete this major project in just five months – from engineering and supply through installation (including power supply, cable routing, and control) all the way to commissioning and documentation.

Superior trace heating

500 detailed technical drawings and 2,000 person-hours are evidence of the scale of the task that BARTEC successfully completed –as requested – in just five months. The team comprised more than 60 experts in engineering, logistics management, construction management, assembly, quality management, and health and safety. The BARTEC components, which have a combined consumption of 1.7 megawatts, are used in a wide range of areas. As well as the production, storage, and transport of the bitumen, these areas also include pumping stations, pipelines for crude oil and refined products, as well as the gas flare and truck and train loading stations.

Ingenious solutions save costs

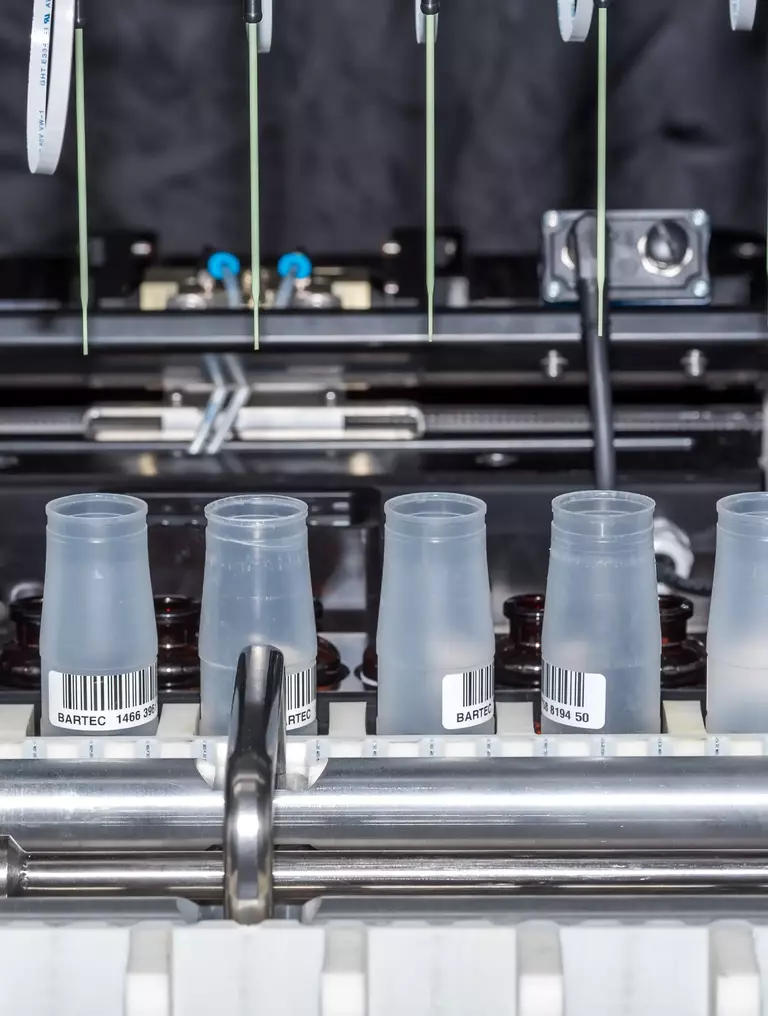

The BARTEC team used three different types of heat trace cables, to suit the site’s differing requirements. Around the bitumen production area, they installed mineral-insulated, single-core heating cable. This is particularly robust and therefore requires no additional protection. This solution also ensures constant power output per meter and is highly resistant to chemicals and stress corrosion.

In order to provide frost protection for the eight kilometers of pipeline in the light distillates and gas oils depot, as well as the pumping stations and diesel loading stations, BARTEC also installed self-limiting parallel heating tapes that can be used without temperature limiters, even in hazardous areas. This also saves both material and costs, especially as the parallel power supply allows the heating tape to be conveniently cut to any length.

The third and final type are the extremely flexible and durable polymer-insulated heating cables. These allow heating circuits of over a kilometer in length to be constructed, meaning that the project team was able to save around 60 kilometers of supply and control cable on the main line compared to the original estimates.

Outstanding performance

For the new bitumen plant in Aktau, BARTEC planned and installed trace heating solutions with a total length of 48 kilometers. On top of this came 600 Ex e terminals, 16 control cabinets, and 40 kilometers of power supply and control cable. The successful implementation of this project allowed the world leader in explosion protection to once again prove its expertise and its ability to meet the most diverse requirements of the global markets.

About Caspi Bitum

Caspi Bitum LLP is a joint venture between Kazakhstan and China and the largest producer of road bitumen in the Republic of Kazakhstan. The bitumen plant in Aktau on the Caspian Sea was constructed as part of the state program to boost Kazakhstan’s industrial development. Building work began in 2010, and the plant was opened in 2013 in order to spearhead Kazakhstan’s production of road bitumen.