Hydrogen's versatility lies in its ability to be produced through various methods, including electrolysis, steam methane reforming, and gasification of biomass. The production methods determine the environmental impact and sustainability of hydrogen, with a growing emphasis on green hydrogen produced using renewable energy sources, which is at the forefront of the shift towards sustainability. By leveraging solar, wind, or hydropower to produce hydrogen through electrolysis, the environmental footprint of hydrogen production is significantly reduced. This green variant has the potential to play a key role in decarbonizing sectors that are challenging to electrify directly, such as heavy industry and long-haul transportation.

Hydrogen can be used as a feedstock, a fuel, or an energy carrier and storage, and has many possible applications across industry, transport, power, and buildings sectors. Most importantly, it does not emit CO2 and almost no air pollution when used. It thus offers a solution to decarbonize industrial processes and economic sectors where reducing carbon emissions is both urgent and hard to achieve.

Today, the rapid cost decline of renewable energy, technological developments, and the urgency to drastically reduce greenhouse emissions, are opening new possibilities. Hydrogen has a strong potential to bridge some of this gap, as a vector for renewable energy storage, alongside batteries, and transport, ensuring backup for seasonal variations and connecting production locations to more distant demand centers.

Furthermore, hydrogen can replace fossil fuels in some carbon-intensive industrial processes, such as in the steel or chemical sectors, lowering greenhouse gas emissions and further strengthening global competitiveness for those industries. It can offer solutions for hard-to-abate parts of the transport system, in addition to what can be achieved through electrification and other renewable and low-carbon fuels. A progressive uptake of hydrogen solutions can also lead to repurposing or re-using parts of the existing natural gas infrastructure, helping to avoid stranded assets in pipelines.

Given its unique properties, such as high flammability and low ignition energy, ensuring explosion protection becomes paramount. Its combustion produces intense heat, featuring a flame that is not visible to the human eye. In discussions concerning safety and explosion prevention, concerns and inquiries often emerge regarding hydrogen. In the case of extensive facilities, the implementation of novel explosion protection systems becomes imperative, catering to various applications and we as BARTEC are proud to offer solutions for explosion protection in the hydrogen market.

BARTEC - your trusted partner in hydrogen production, transport and consumption

To accompany our customers with technical expertise and the right applications in the best possible way, BARTEC is already positioning itself for this change in the new energy sector. As a facilitator, enabler and trusted partner, BARTEC supports our customers in safe energy production, transport, and industrial consumption of hydrogen.

Within BARTEC, a cross-functional team is working on thinking through potential customer needs and future applications. The goal: developing safety solutions that enable our customers to apply their technology within the hydrogen industrial environments and enable safe handling.

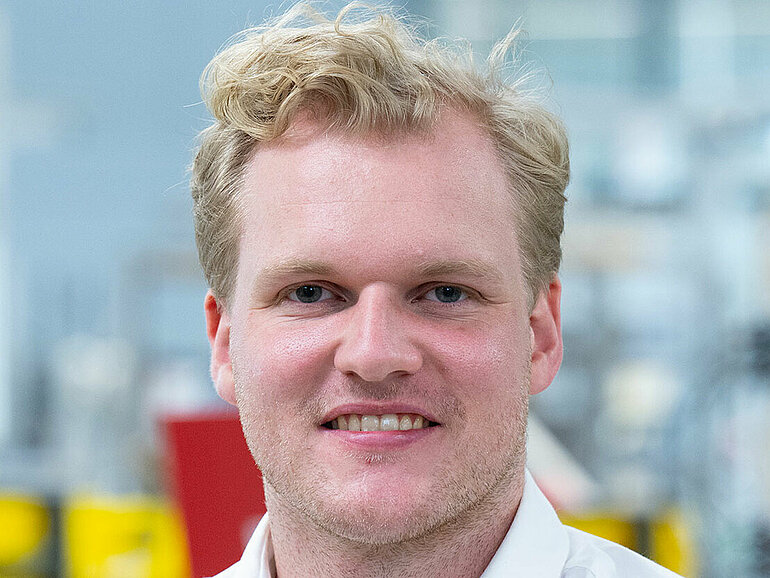

Janis Wagner, VP Corporate Development & M&A explains: “We are committed to helping our clients make the transition to new energy sources while ensuring the safe and efficient operation of established technologies and processes. We take a holistic view of market dynamics, mirror them with our own capabilities and clearly define our growth areas.’’

He follows with: ‘’BARTEC is ready for action in the safe realization of hydrogen applications. Most of our products have already been certified for the use of hydrogen for many years. We have the experience with hydrogen applications in the chemical and energy industries and 90 percent of the portfolio is already available for these applications.’’

Furthermore, new product lines for hydrogen transport have been developed, combining measurement technology, product monitoring, and data transmission. This way, we can ensure to our customers that the compressed hydrogen inside can be safely loaded and unloaded.

Marco Bekker, Business Development Manager Hydrogen at BARTEC Netherlands, explains more about BARTEC’s readiness for new energy developments in hazardous areas: ‘’BARTEC’s product portfolio is ready to serve both the already existing “new energy” applications as well as all new or specific upscaled hydrogen applications. This is just based on the fact that hydrogen (or methanol and ammonia) is not a newly invented gas. Hydrogen has been known for more than 250 years, and it is among others used in large-scale petrochemical industries.”

Therefore, BARTEC’s electrical equipment for use in hazardous areas is already classified for use in areas with hydrogen under IECEx and ATEX. Recently, BARTEC has also supported many OEM customers to make their equipment ready to be used with hydrogen, thereby applying years of exification knowledge.

Beyond that, we have product offerings that are specifically designed for or of specific interest for hydrogen application, such as the metering systems for hydrogen truck trailers offered and the trace moisture measurement systems.”

With its potential to address pressing environmental concerns and serving as a catalyst for a clean energy transition, hydrogen is poised to shape the future. As technological advancements and international collaborations accelerate, the world is on the cusp of a hydrogen revolution, ushering in an era where this versatile gas becomes a cornerstone of a sustainable and resilient energy landscape and BARTEC is proud to be one of the key players in the hydrogen market for explosion protection industry with which we are contributing to a safe transition to new energy sources.